Slip Sheets: The Game-Changer in Packaging & How to Pick the Right Material

category:Industry News

time:2025-10-24 16:00:53

In the fast-paced world of logistics and retail packaging, efficiency and cost-effectiveness are always top priorities. If you’re involved in supplying international retailers like Sam’s, Walmart, or Costco, you’ve probably heard of slip sheets— the innovative alternative to traditional wooden or plastic pallets that’s revolutionizing POD (Proof of Delivery) bulk tray packaging. But with two main material options on the market—kraft paper slip sheets and plastic slip sheets—how do you choose the one that fits your business needs? Let’s break it down.

In the fast-paced world of logistics and retail packaging, efficiency and cost-effectiveness are always top priorities. If you’re involved in supplying international retailers like Sam’s, Walmart, or Costco, you’ve probably heard of slip sheets— the innovative alternative to traditional wooden or plastic pallets that’s revolutionizing POD (Proof of Delivery) bulk tray packaging. But with two main material options on the market—kraft paper slip sheets and plastic slip sheets—how do you choose the one that fits your business needs? Let’s break it down.

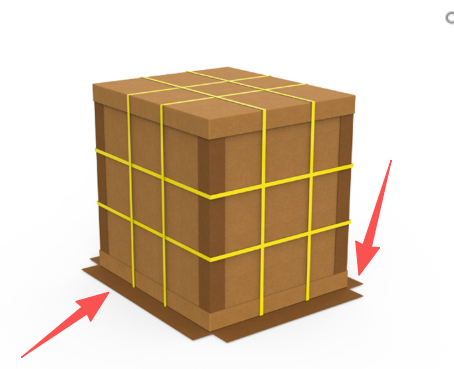

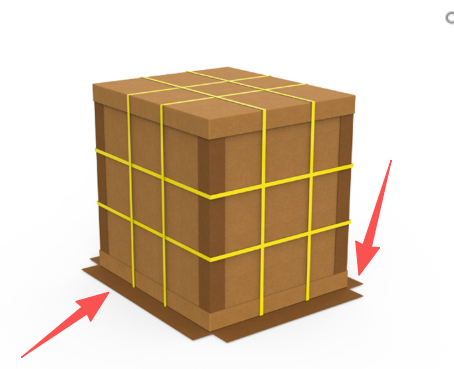

First, What Exactly Is a Slip Sheet?

Before diving into material selection, let’s clarify what makes slip sheets a standout choice. A slip sheet is a thin, flat sheet (typically ranging from 1mm to 5mm thick, depending on material and load requirements) designed to support stacked goods. Unlike traditional pallets, which add weight, bulk, and storage costs, slip sheets are lightweight, space-saving, and compatible with standard forklifts equipped with a push-pull attachment. This makes them ideal for tight shipping containers, reducing dimensional weight charges, and streamlining warehouse storage—no more bulky pallets taking up valuable space!

The Two Core Materials: Kraft Paper vs. Plastic

Each slip sheet material has unique properties tailored to specific use cases. Understanding their strengths and limitations is key to making the right choice.

1. Kraft Paper Slip Sheets

Kraft paper slip sheets are made from high-strength, virgin or recycled kraft paper, often reinforced with layers to boost load-bearing capacity (usually supporting 1,000kg to 2,000kg per sheet, depending on thickness). Their biggest selling points lie in sustainability and cost-effectiveness for one-way shipping.

One of the most notable advantages of kraft paper slip sheets is their eco-friendliness. They’re 100% biodegradable and recyclable, aligning with the growing demand from retailers and consumers for sustainable packaging solutions. Additionally, they’re extremely lightweight—often weighing less than 500g per sheet— which translates to lower shipping costs, especially for international shipments where weight is a major cost factor. They also fold flat when not in use, minimizing storage space at your facility.

That said, kraft paper slip sheets do have limitations. They’re not waterproof, so they’re best used for dry goods (like electronics, textiles, or non-perishable food items) and in controlled environments where moisture isn’t a concern. They’re also designed for one-way use—while some can be reused a few times, they lack the durability for long-term circulation.

2. Plastic Slip Sheets

Plastic slip sheets are crafted from high-density polyethylene (HDPE) or polypropylene (PP), offering exceptional durability and versatility. They’re available in solid, corrugated, or ribbed designs, with load-bearing capacities ranging from 1,500kg to 3,000kg—making them suitable for heavier loads like machinery parts, glassware, or wet goods.

Durability is the plastic slip sheet’s superpower. They’re water-resistant, impact-resistant, and resistant to tears, scratches, and most chemicals—perfect for harsh warehouse environments, refrigerated shipping, or outdoor storage. Unlike kraft paper versions, plastic slip sheets are built for repeated use; with proper care, they can last for years, making them a cost-effective choice for long-term operations.

Another benefit is their consistency. Plastic slip sheets maintain their shape and strength even under extreme temperatures (from -20°C to 60°C for most HDPE sheets), ensuring reliability across different climates—critical for domestic warehouse turnover where goods may move between heated and unheated spaces. They’re also easy to clean, which is a must for industries like food and beverage or pharmaceuticals that require strict hygiene standards.

The main tradeoffs? Plastic slip sheets have a higher upfront cost compared to kraft paper options, though this is offset by their reusability. They’re also less eco-friendly than paper, though many manufacturers now offer recycled plastic versions to mitigate this concern. Additionally, they’re slightly heavier than paper sheets, though the difference is often negligible for domestic shipping.

How to Choose: Match Material to Your Use Case

The decision ultimately comes down to two key factors: whether you need recycling/reusability and your shipping destination. Here’s a clear, actionable guide:

Choose Kraft Paper Slip Sheets If…

- You’re shipping goods internationally (to Sam’s, Walmart, or Costco’s global warehouses) with no need for return or recycling. The lightweight design cuts shipping costs, and the biodegradable material avoids cross-border waste disposal issues.

- Your products are dry and stored in controlled environments. Avoid using them for wet, oily, or outdoor-stored goods.

- Sustainability is a top priority for your brand. Kraft paper aligns with eco-labels and retailer sustainability mandates.

- You’re looking for a low upfront cost for one-way shipments. Kraft paper is more affordable per unit for single-use scenarios.

Choose Plastic Slip Sheets If…

- You’re using slip sheets for domestic warehouse turnover—moving goods between your facility, distribution centers, and local retail stores. The reusability ensures long-term value.

- Your products are heavy, wet, or require protection from moisture/chemicals. Plastic’s durability and water resistance make it ideal for these scenarios.

- You need consistency across harsh environments (e.g., refrigerated warehouses, construction sites). Plastic maintains strength in extreme temperatures.

- You want to minimize long-term costs. While the upfront investment is higher, plastic slip sheets’ reusability (50+ uses in many cases) lowers the total cost of ownership.

Final Tips for Success

No matter which material you choose, there are a few best practices to maximize efficiency:

1. Check load requirements: Work with your supplier to select the right thickness—overloading can lead to sheet damage.

2. Ensure forklift compatibility: Make sure your team’s forklifts have push-pull attachments (most retailers also require this).

3. Test in your environment: If you’re unsure, request samples to test with your products and storage conditions.

Slip sheets are more than just a packaging trend—they’re a strategic tool to cut costs, save space, and meet retailer demands. By aligning the material with your shipping goals and product needs, you’ll unlock their full potential for your business.

National service hotline:+86(0)755-2898 7706

National service hotline:+86(0)755-2898 7706